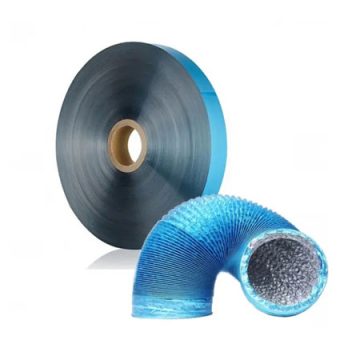

Aluminum pet foil for flexible ducting

Products description

- Quality control :under ISO standards and RoHS compliant.

- HS code :7607.20

- Structure:Single side aluminum foil : AL+PET ;Double side aluminum foil AL+PET+AL;

- Color:Silver;blue ,white,gold color

- Width: 30-100mm for duct application

- Inner core size : 3"(76mm) ,6"(152mm)

- Outer Diameter: 400-550mm as normal OD

- MOQ:200-500 KGS

Technical parameters

| Structure | Thickness(μm) | Weight(g/m2) | Yield(m2/kg) |

| 6AL+12PET | 20~21 | 36.3 | 27.4 |

| 7AL+12PET | 21~22 | 37.6 | 26.6 |

| 9AL+12PET | 23~24 | 43.2 | 23.1 |

| 9AL+15PET | 26.5~27 | 47.3 | 21.1 |

| 9AL+20PET | 31~32 | 55.3 | 18.1 |

| 9AL+25PET | 36~38 | 62.7 | 15.9 |

| 14AL+12PET | 28.5~29.5 | 57.28 | 17.4 |

| 6AL+12PET+6AL | 26~28 | 51.67 | 19.3 |

| 7AL+12PET+7AL | 29~31 | 57.28 | 17.4 |

| 9AL+12PET+9AL | 33~34 | 68.5 | 14.5 |

| 6AL+15PET+6AL | 30~32 | 58.4 | 17.1 |

| 9AL+15PET+9AL | 37~39 | 74.6 | 13.3 |

We offer high-quality aluminum foil products specially designed for flexible duct applications. Our range includes both single-sided and double-sided aluminum polyester (AL/PET) foil, manufactured to meet industry standards for durability, flexibility, and performance.

Commonly used specifications include AL6/PET12, AL7/PET12, AL6/PET15, and AL6/PET15/AL6. These structures combine the excellent barrier and reflective properties of aluminum with the strength and flexibility of polyester film, providing reliable insulation and vapor barrier functions. The single-sided foils are ideal for general duct wrapping, while the double-sided AL6/PET15/AL6 structure offers enhanced protection and reflectivity, making it suitable for more demanding applications.

Our aluminum PET foils are produced with high consistency, smooth surfaces, and stable adhesive compatibility, ensuring optimal performance in HVAC and duct insulation systems. Whether for residential, commercial, or industrial projects, our foils deliver long-lasting protection and improved energy efficiency.

The aluminum pet foil used in the ventilation pipe have good ductility, plasticity and strength. This ensures that operations such as folding, compression and connection can be carried out smoothly during the production process, and can withstand the pressure under normal conditions of use.

Aluminum PET foil has good corrosion resistance and can resist the erosion of air duct materials by environmental factors such as oxidation, acid and alkali. Secondly, the material has high strength and rigidity, and it is not easy to deform or break during use. In addition, the aluminum pet foil also has the characteristics of light weight, easy processing .

By applying aluminum pet tape to air duct, many benefits can be achieved. First, the use of this material in air conditioning systems can improve the energy efficiency of the overall system. Because of the low thermal conductivity of the aluminum pet tape, it can reduce the loss of cold air and heat transfer loss; It also reduces noise and vibration during system operation.

The use of aluminum pet tape to make air ducts inside buildings can also improve indoor air quality. The material is non-toxic and tasteless, and the surface is smooth and flat, and will not release any harmful substances into the air; It also avoids problems such as bacterial growth and dust accumulation.

The appropriate thickness is one of the key factors to ensure the effective function of the aluminum foil ventilation pipe. Thin or too thick aluminum pet foil will affect its thermal conductivity and durability. Therefore, it is necessary to determine the appropriate thickness according to the actual demand in the selection.