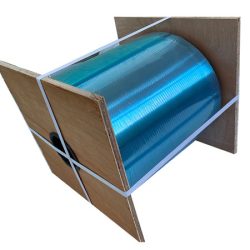

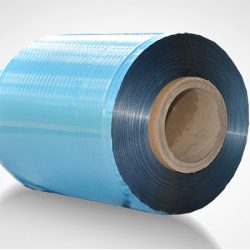

Aluminum pet mylar tape by cross-winding spool

Products description

- Quality control :under ISO standards and RoHS compliant.

- HS code :7607.20

- Color: Silver ,copper color,blue

- Spool tube height: 100mm-360mm

- Cross winding edge :10-15mm per side

- Cross winding length:3000m to 35000m but not more than 35KG/spool

- Inner core size (ID): 3"(76mm)

- Tube material:Paper core

Technical parameters

| Structure | Thickness(μm) | Weight(g/m2) | Yield(m2/kg) |

| 9AL+15PET | 26.5~27 | 47.3 | 21.1 |

| 9AL+12PET | 23~24 | 43.2 | 23.1 |

| 12AL+12PET | 26~27 | 52.2 | 19.1 |

| 20AL+20PET | 42~43 | 85.1 | 11.7 |

| 25AL+12PET | 40~41 | 88.17 | 11.3 |

| 25AL+25PET | 53~54 | 105.69 | 9.5 |

| 40AL+12PET | 55~57 | 128.1 | 7.8 |

| 30AL+23PET | 56~59 | 116.4 | 8.6 |

| 50AL+20PET | 73~76 | 166.4 | 6.0 |

| 40AL+23PET | 67~69 | 146.7 | 6.8 |

When comparing aluminum polyester tape packaging, spools offer distinct advantages over pads, especially for industrial and manufacturing purposes. The aluminum polyester tape, with a total thickness ranging from 40 microns to 75 microns, is commonly supplied on spools for ease of use, precision, and efficiency in production processes.

One of the key benefits of using spools is their continuous, uninterrupted feed, which allows for more consistent application during manufacturing. This ensures a smoother and faster production flow, reducing the chances of handling errors or waste. Additionally, spools provide better storage and handling convenience, as they allow for more organized and compact storage compared to pads, which can be bulkier and harder to manage.

Spools are also more suitable for automated processes, as they can be directly integrated into machinery for precise dispensing. This improves overall productivity, especially for large-scale production runs. Moreover, spooled aluminum polyester tape minimizes the risk of physical damage or misalignment during transport and handling, ensuring the material stays intact and ready for use.

Overall, spooled aluminum polyester tape offers superior practicality, efficiency, and performance for manufacturers, making it the preferred choice in industries where time, space, and precision are crucial.